No products in the cart.: ₨0.00

NEED HELP

+92 326 0334630

+923090549911

+923090549911

WHAT ARE YOU LOOKING FOR?

QUICK LINKs

Login

No account yet? Create an account

Register

Have an Account. Login

Launch or grow your clothing brand with end-to-end manufacturing, printing, stitching, and packaging all under one roof.

Welcome to your all-in-one textile solution provider. Whether you’re launching a new clothing brand or scaling an existing one, we offer comprehensive services: fabric sourcing, textile printing, embroidery, stitching, packaging, private labeling, and more. We handle every detail so you can focus on building your brand.

At UTM Corporation, we believe in empowering clothing brands from their very first sketch to the final packaged product ready for sale. Our journey began with a vision: to provide a seamless production pipeline for brands, eliminating the hassle of coordinating multiple vendors.

We combine decades of textile experience with modern manufacturing, printing, embroidery, and packaging technology to deliver high-quality, consistent results. Our team of skilled craftsmen, technicians, and design specialists works closely with every client, whether a new startup or an established brand, to fulfill custom requirements with precision and care.

Our mission is simple: to be your trusted manufacturing partner in clothing. We aim to make brand development easier, faster, and more reliable, so you can focus on creativity, design, and growth.

We offer a full range of services tailored to clothing brands. Whether you need a single service or full-scale end-to-end production, we’ve got you covered.

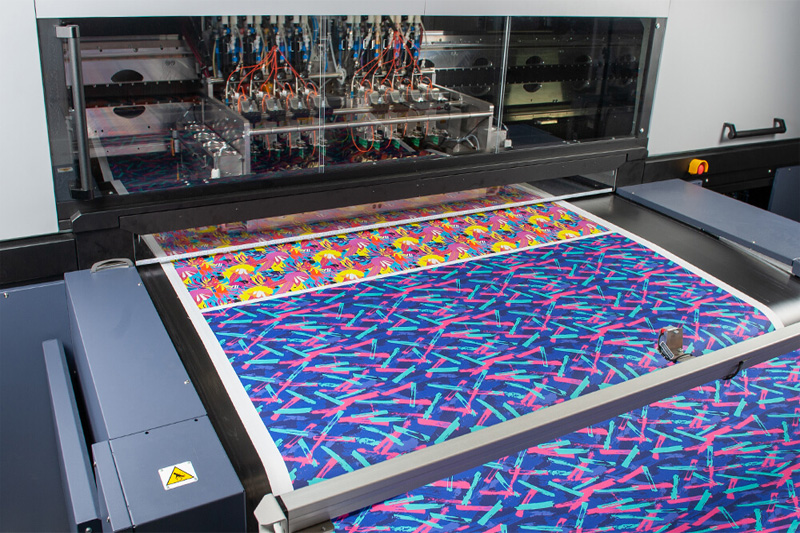

Flatbed printing can be considered an automated version of the older hand-operated silkscreen printing process used on t-shirts, sweatshirts, and other printed items. For each color in the print design, a separate screen must be constructed or engraved. If the design has four colors, then four separate screens must be engraved.

The modern flatbed printing machine consists of an infeed device, a glue trough, a rotating continuous flat rubber blanket, flat bed print table harness to lift and lower the flat screens, and a squeegee.

he infeed device allows for precise straight feeding of the fabric onto the rubber blanket, as the cloth is fed to the machine it is lightly glued to the blanket to prevent any shifting of the fabric or distortion during the printing process. The blanket carries the fabric under the screens which are in the raised position.

Once under the screens, the fabric stops. The screens are lowered and then the automatic squeegee moves across each screen pushing print paste through the design or open areas through the screens. The screens are raised, the blanket precisely moves the fabric to the next color and the process is repeated. Once each color has been applied the fabric is removed from the blanket. The fabric moves through the required fixation process. The rubber blanket is continuously washed, dried, and rotated back to the fabric infeed area.

Sign up to receive information about new arrivals and special promotions.

Pakistan

silkotextiles@gmail.com

+92 4235113341

+92 4235118064